Rigid membrane switch is one of the common human-machine interface products. We offer a variety of product categories and options for appliance, industrial and medical applications. Whether your application requires the use of pressure-touch, pressure-free touch, silicone, hard-coated, flexible or rigid PCBs, Smartart can provide solutions through our extensive in-house manufacturing capabilities. We are able to provide a full range of options and customizations to meet the customer’s desired functionality, appearance, and more.

Cover Sheet Materials – We offer a variety of substrates such as PET, PC, PVC, ceramic, silicone, and more.

Touch – Membrane switches can be designed as pressure touch or non-pressure touch.

Graphic Design – We can provide a variety of textures, UV coatings and graphic design options, including 2-10 color designs and full image designs.

Finish Options – We can offer soft touch, embossed and other types of finishes.

Connection method | Cover material | Coating / Decoration | Additional options |

Pin connection | PC | Screen printing | LED/EL backlight |

USB | PVC | Transparent or translucent windows | Polyester fiber, PC, PET, PVC, silicone substrate |

FPC | FPC | UV hard coating surface treatment | EMI interference resistance |

— | PET | Selective texture | Plastic and metal tactile domes/switches |

— | — | Graphic overlay | Spacer and seal combination |

— | — | — | backplane |

Parameter | Options & Notes |

Size | As per customer requirements |

Structure / Construction | Flat / Embedded Switching / Raised Switching / Overlays |

Integration | Waterproof and dustproof gaskets available |

Cover Materials | PC, PVC, PET, Silicon, Polyester |

Thickness | PET: 0.08 – 0.25mm PC: 0.175 – 0.35mm |

Decoration | Screen printing, transparent or tinted windows, graphic overlays |

Additional Options | UV hard-coat surface, various textures |

Interface Options | Pin, FFC, FPC, USB |

Pin Spacing | 2.54 / 1.25 / 1.0mm |

Housing | Female, 2.54mm |

Circuit Material | Silver Paste, Carbon Paste, Copper Circuit |

Rated Current | 35V, 100mA, 1W |

Response Time | ≤ 5 ms |

Insulation Resistance | >100MΩ 250V DC |

Operating Voltage | <50V DC |

Contact Travel | 0.1 – 0.4mm (non-tactile) | 0.4 – 1mm (tactile) |

Actuation Force | 50 – 350g (non-tactile) | 200 – 750g (tactile) |

Lifespan | ≥1 million actuations |

Contact Travel | 0.1 – 0.4mm (non-tactile) | 0.4 – 1mm (tactile) |

Actuation Force | 50 – 350g (non-tactile) | 200 – 750g (tactile) |

Lifespan | ≥1 million actuations |

Contact Travel | 0.1 – 0.4mm (non-tactile) | 0.4 – 1mm (tactile) |

Actuation Force | 50 – 350g (non-tactile) | 200 – 750g (tactile) |

Lifespan | ≥1 million actuations |

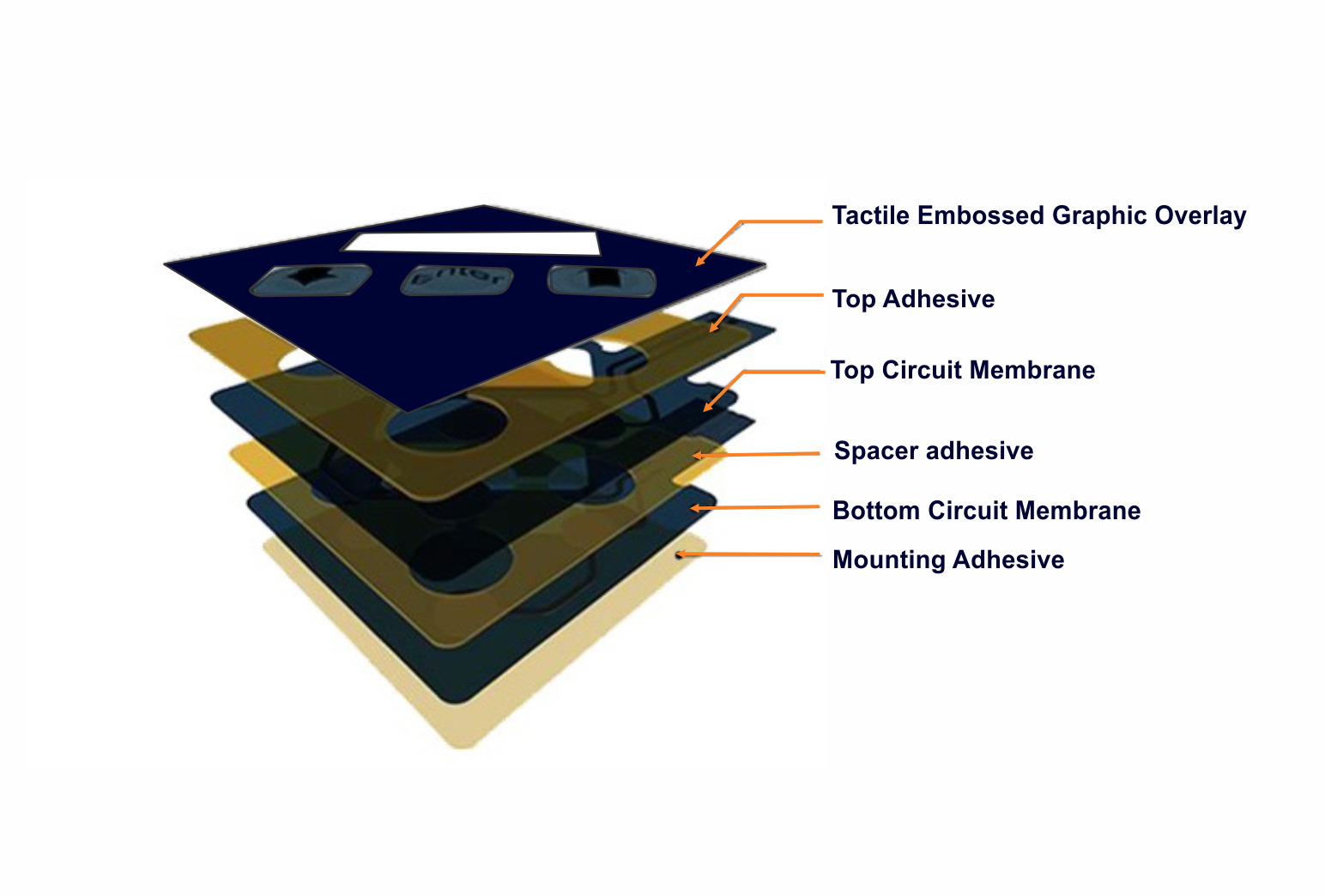

Rigid Membrane switches are essentially a sandwich of thin layers that are bonded together using pressure sensitive adhesives. Depending on the application requirements, a membrane switch will consist of as few as 4, and as many as 9 layers. In contrast to mechanical switches, membrane switches offer the advantage of lower cost, they consume less design space with their low profile, are easy to clean, and they offer a sleeker, ergonomic, and aesthetically pleasing appearance.

The visible top layer of a membrane switch is the graphic overlay, with printed circuitry underneath the overlay. The circuitry can also incorporate different layers such as polyester (silver flex), polyimide (copper flex), and rigid PCB layers. Activation of a switch occurs when a printed shorting pad or metal dome makes contact with the bottom circuit layer thus, closing the circuit.

Plot No - 3, Zeta-1, Greater Noida Gautam Budh Nagar-201306

+91 8130889285 +91 8368416257

pankaj@smartartprintechsolutions.com Kundan@smartartprintechsolutions.com

Copyright © 2024 Smartart Printech Solutions LLP